The Evolution of Industrial Donut Machines

Industrial donut machines have come a long way from their humble beginnings. Initially, donut production was a labor-intensive process, relying heavily on manual labor to mix, shape, and fry the dough. However, with the advent of industrial machines, the process has become significantly more efficient and reliable. These machines are engineered for mass production environments where speed, consistency, and reliability are critical. Leading suppliers now offer fully automated donut-making systems that integrate seamlessly into industrial food manufacturing lines. This evolution has allowed bakeries and food factories to meet the increasing demand for donuts with ease.

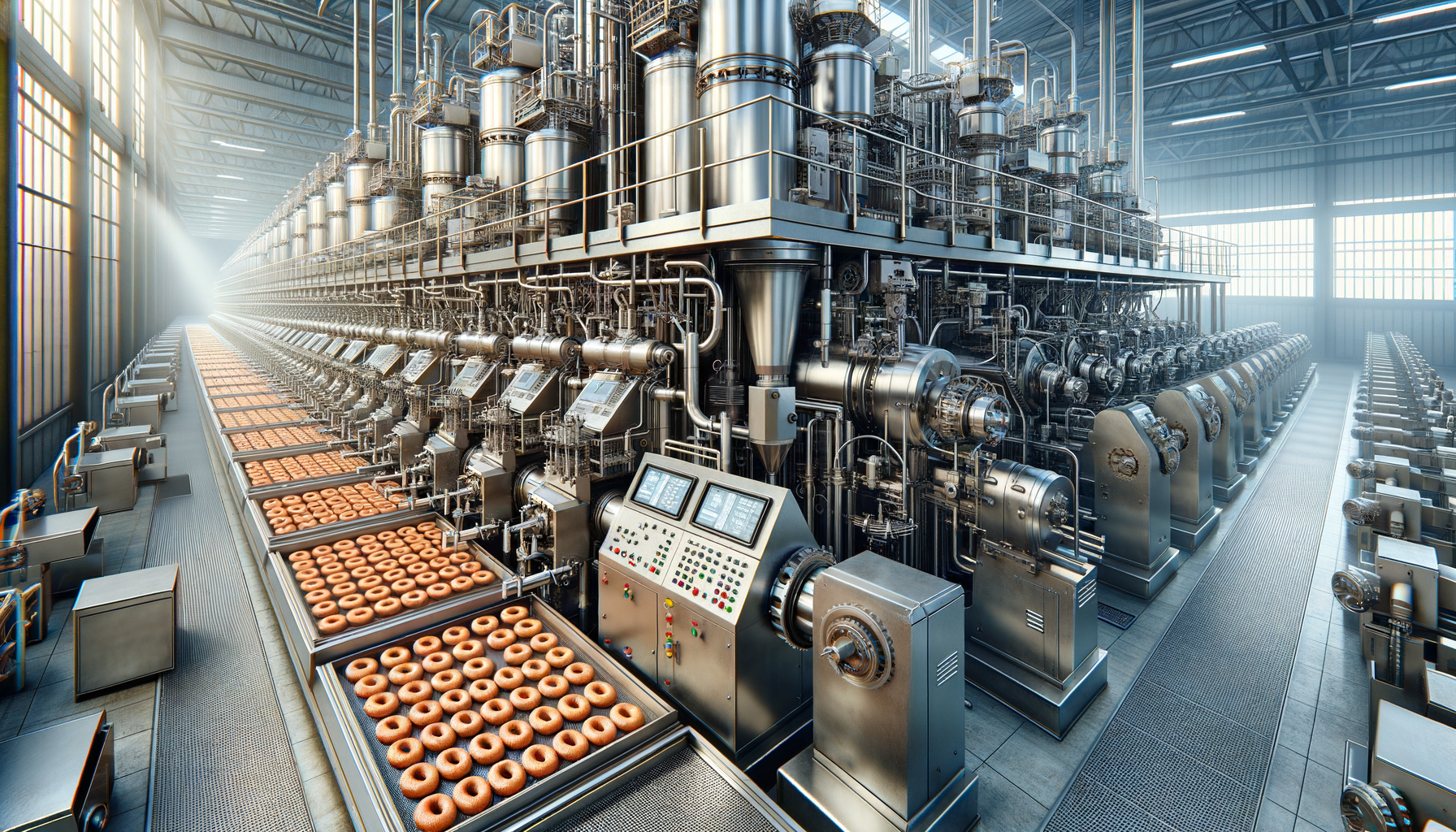

Modern industrial donut machines offer a range of features that enhance productivity and product quality. These include automated dough handling, precision frying, and advanced glazing systems. The integration of these features ensures that each donut is produced to exact specifications, reducing waste and increasing yield. Furthermore, the ability to produce a continuous output streamlines operations, making it easier for businesses to scale up production as needed.

Key Features of High-Capacity Donut Production Equipment

High-capacity donut production equipment is designed to meet the rigorous demands of large-scale operations. One of the standout features of these machines is their ability to produce donuts at a rapid pace without compromising quality. This speed is achieved through advanced automation technology that manages every aspect of the production process, from mixing and shaping to frying and glazing.

Another critical feature is the consistency these machines provide. By automating the production process, manufacturers can ensure that each donut is identical in size, shape, and taste. This uniformity is essential for maintaining brand reputation and meeting consumer expectations. Additionally, the machines are equipped with user-friendly interfaces, allowing operators to easily adjust settings and monitor production in real-time.

- Automated dough mixing and shaping

- Precision frying systems

- Advanced glazing and decorating options

- Real-time monitoring and control

These features collectively contribute to the exceptional quality of donuts produced by high-capacity equipment, making them a valuable asset for any large-scale bakery operation.

Choosing the Right Industrial Machine Supplier

When selecting an industrial machine supplier for donut production equipment, it’s crucial to consider several factors to ensure you’re making a well-informed decision. Firstly, evaluate the supplier’s reputation in the industry. Trusted industrial equipment manufacturers are known for their reliable and durable machinery, backed by positive customer reviews and testimonials.

Another important aspect is the range of products offered. A supplier that provides a variety of machines tailored for different production needs can offer more customized solutions. Additionally, consider the level of customer support and after-sales service provided. Reliable suppliers offer comprehensive support, including installation, training, and maintenance services, ensuring that your equipment operates smoothly over its lifespan.

Lastly, assess the supplier’s commitment to innovation. Suppliers that invest in research and development often offer cutting-edge technology that can enhance your production capabilities and keep you ahead of industry trends. By carefully evaluating these factors, you can choose a supplier that aligns with your operational goals and provides the necessary support for your business’s success.

Integration of Donut Machines in Food Manufacturing Lines

The integration of donut machines into existing food manufacturing lines is a critical step for businesses looking to optimize their production processes. Seamless integration ensures that the new equipment complements the existing infrastructure, enhancing overall efficiency and productivity.

To achieve successful integration, it’s essential to conduct a thorough assessment of your current manufacturing setup. This assessment helps identify any potential bottlenecks or compatibility issues that may arise when introducing new equipment. Working closely with your machine supplier can facilitate this process, as they can provide insights and recommendations based on their expertise.

Once the assessment is complete, the next step is to develop a detailed implementation plan. This plan should outline the installation process, including timelines, resource allocation, and any necessary modifications to the existing setup. By following a structured approach, businesses can minimize disruptions and ensure a smooth transition to the new production system.

Benefits of Automated Donut Production Systems

Automated donut production systems offer numerous benefits that can significantly impact a business’s bottom line. One of the most notable advantages is the increase in production capacity. With automated systems, businesses can produce a higher volume of donuts in a shorter amount of time, meeting the demands of large-scale operations and expanding their market reach.

Additionally, these systems enhance product consistency and quality. Automation reduces the likelihood of human error, ensuring that each donut meets the same high standards. This consistency is crucial for maintaining customer satisfaction and loyalty.

Moreover, automated systems contribute to cost savings by reducing labor costs and minimizing waste. The precision and efficiency of automated processes lead to better resource utilization, ultimately improving profitability. Lastly, the scalability of automated systems allows businesses to adapt to changing market demands with ease, providing a competitive edge in the dynamic food industry.

Leave a Reply