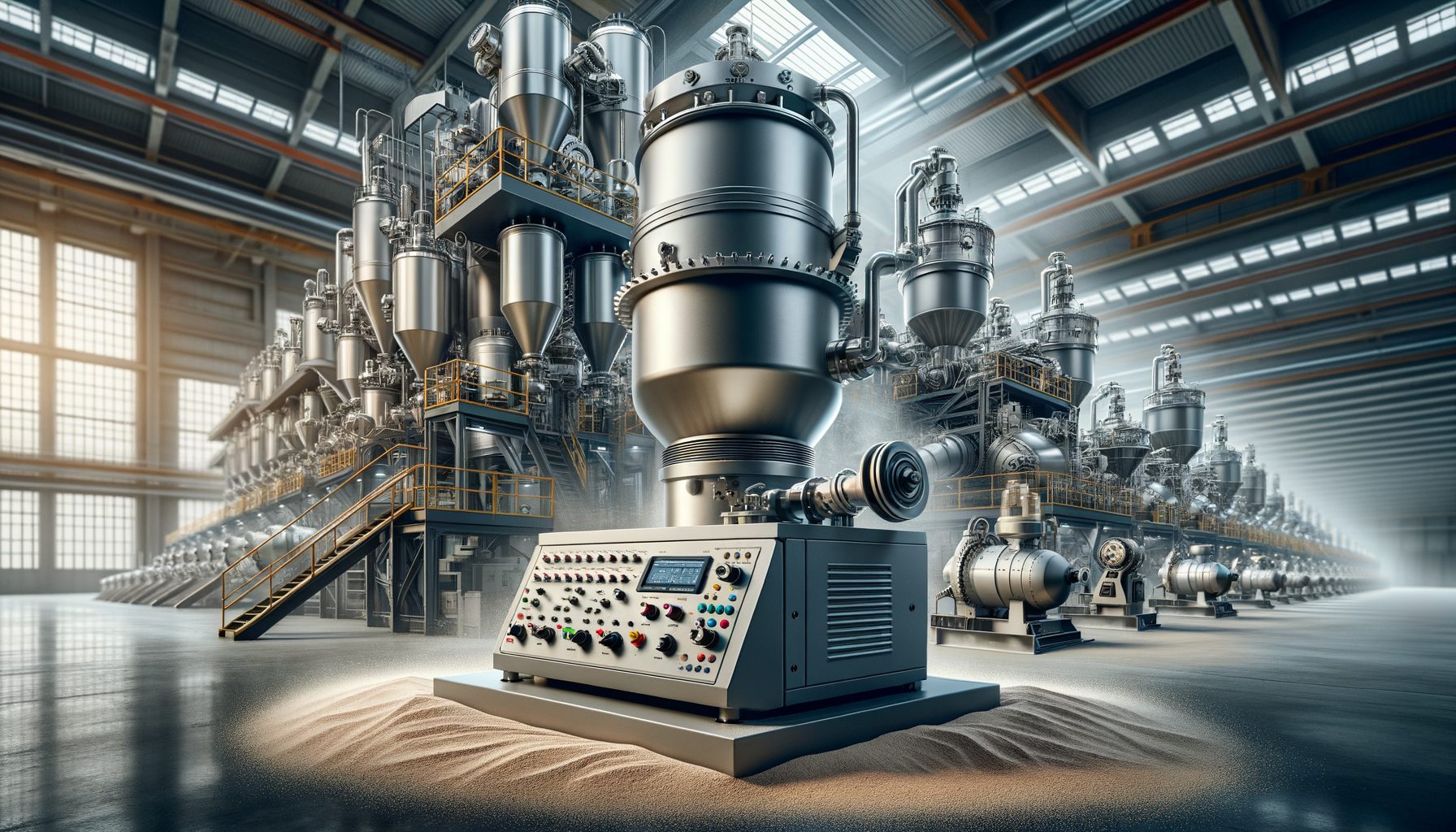

Introduction to Dry Powder Blender Mixer Machines

In the world of industrial-scale production, consistency and efficiency are crucial. Dry powder blender mixer machines have emerged as pivotal equipment across various sectors, including pharmaceuticals, nutrition, and chemicals. These machines are designed to ensure uniform blending, which is essential for the quality and efficacy of the final product. Whether it’s mixing ingredients for a nutritional supplement or creating a chemical compound, the right blender mixer can make all the difference. This article delves into the various aspects of these machines, exploring their importance, features, and the considerations for selecting the right one for industrial applications.

Key Features of Industrial Dry Powder Blenders

Industrial dry powder blenders are equipped with features that cater to large-scale production needs. One of the primary features is the ability to achieve uniform mixing, which is vital for maintaining product quality. These machines often come with advanced control systems that allow operators to monitor and adjust the blending process to ensure consistency.

Another significant feature is dust control. In industries where fine powders are handled, dust generation can be a major concern. Modern blenders are designed to minimize dust, ensuring a cleaner and safer working environment. Additionally, many machines are built with robust construction materials that offer durability and longevity, reducing the need for frequent maintenance.

Some of the other features that enhance the functionality of these machines include:

- High-speed blending capabilities

- Versatile design to handle different types of powders

- Energy-efficient operation

- Easy cleaning and maintenance

Applications in Various Industries

The versatility of dry powder blender mixers makes them suitable for a wide range of industries. In the pharmaceutical industry, these machines are used to blend active ingredients with excipients to create tablets and capsules. The precise mixing capabilities ensure that each dosage contains the correct amount of active ingredient, which is crucial for the drug’s efficacy and safety.

In the nutrition sector, blender mixers are employed to create supplements and meal replacements. The ability to mix powders evenly ensures that each serving provides the intended nutritional benefits. Similarly, in the chemical industry, these machines are used to combine raw materials to produce a variety of chemical products.

Other industries that benefit from these blenders include:

- Food processing

- Cosmetics

- Construction materials

Each industry has specific requirements, and choosing the right blender mixer involves considering the unique needs of the production process.

Considerations for Selecting a Blender Mixer

When selecting a dry powder blender mixer for industrial applications, several factors must be considered to ensure optimal performance and efficiency. One of the primary considerations is the capacity of the machine. It’s essential to choose a blender that can handle the volume of material required for production without compromising on quality.

The type of material being mixed is another important factor. Some powders may require specific types of blades or mixing mechanisms to achieve the desired consistency. Additionally, the ease of cleaning and maintenance should be considered, especially in industries where hygiene is critical.

Other considerations include:

- Energy consumption and operational costs

- Compatibility with existing production lines

- Availability of spare parts and technical support

- Compliance with industry regulations and standards

By carefully evaluating these factors, manufacturers can select a blender mixer that meets their production needs while ensuring efficiency and cost-effectiveness.

Conclusion: The Importance of Choosing the Right Blender Mixer

In conclusion, dry powder blender mixer machines play a crucial role in industrial-scale production across various sectors. Their ability to provide consistent blending, control dust, and operate efficiently makes them indispensable in ensuring product quality and safety. As industries continue to evolve, the demand for advanced and reliable blending solutions will only grow.

Choosing the right blender mixer involves understanding the specific needs of the production process and evaluating the features and capabilities of available machines. By investing in a high-quality blender mixer, manufacturers can enhance their production capabilities, reduce operational costs, and maintain a competitive edge in their respective industries.

Leave a Reply