Introduction to Industrial Machines in Food Production

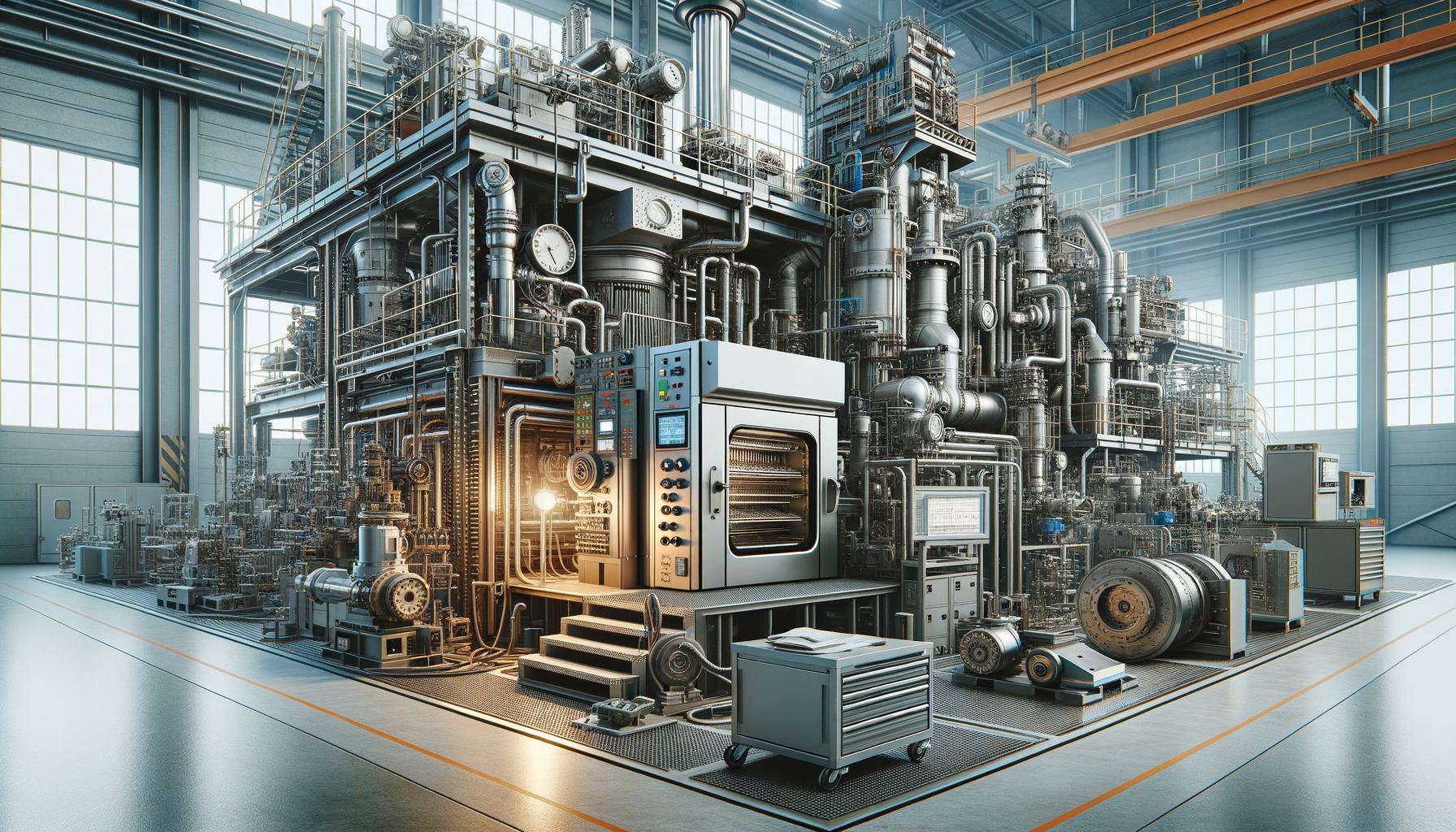

In the realm of food production, industrial machines play a pivotal role in ensuring efficiency and consistency. As the demand for food products increases globally, the need for advanced machinery becomes more pronounced. Leading commercial oven manufacturers have stepped up to meet these demands by offering sophisticated solutions tailored to various food production environments. These machines are not only about baking or cooking; they integrate into larger systems, enhancing the overall workflow and productivity. The evolution of industrial machines, particularly in the baking sector, underscores the importance of innovation and adaptation in meeting commercial standards.

Commercial Oven Manufacturers: Meeting High-Demand Kitchen Needs

Commercial ovens are at the heart of many food production facilities, offering versatility and efficiency. Renowned manufacturers have developed ovens that cater to high-demand kitchens, focusing on speed, precision, and energy efficiency. These ovens come in various types, including convection units and smart steam ovens, each designed to meet specific culinary needs. The innovation in these machines is evident in their ability to maintain consistent temperatures and cooking times, crucial for large-scale operations. By investing in top-rated commercial ovens, businesses can ensure they meet the rigorous demands of food production while maintaining quality and taste.

Integration of Custom Equipment in Industrial Systems

Custom equipment integration is an essential aspect of modern industrial systems. It allows businesses to tailor their machinery to specific production needs, ensuring optimal performance. This customization can include adjustments in size, functionality, or even the integration of new technologies. By working with suppliers who offer customizable options, businesses can enhance their production capabilities and efficiency. The ability to integrate custom equipment seamlessly into existing systems is a testament to the flexibility and innovation of today’s industrial machine suppliers. This adaptability is crucial for businesses looking to stay competitive in a rapidly changing market.

Advantages of Advanced Industrial Machine Solutions

The adoption of advanced industrial machine solutions offers numerous advantages for food production facilities. These machines are engineered for efficiency, reducing energy consumption and minimizing waste. They also improve speed and precision, allowing for consistent, high-quality output. Additionally, advanced machines often come with enhanced safety features, protecting workers and reducing the risk of accidents. By investing in these solutions, businesses can not only improve their operational efficiency but also reduce their environmental footprint, aligning with global sustainability goals.

Conclusion: Boosting Performance in Large-Scale Kitchens

In conclusion, the integration of industrial-grade oven systems and custom equipment into food production facilities is crucial for boosting performance and meeting the demands of large-scale kitchens. By exploring top supplier options and investing in advanced machinery, businesses can enhance their production capabilities, ensuring they meet commercial standards and consumer expectations. The future of food production lies in the ability to adapt and innovate, and industrial machines play a key role in this evolution. As technology continues to advance, the opportunities for improvement and efficiency in the food production sector will only grow.

Leave a Reply